- Ideal for single-storey industrial and commercial buildings Class 7b and 8 buildings of type C construction

- Complies with the requirements of the Building Code of Australia (BCA2004) and endorsed for NCC 2019

- Low-cost, quick installation with no need for specialist trades

- Water, fire and vermin resistant, with no additional coatings required

- Versatile cladding options with a choice of Stramit's cladding profiles that can be either vertically or horizontally orientated

- Acoustic insulation, uniform internal wall appearance and easily painted if required

Where to Buy

Stramit account holders can buy Stramit Uniguard™ Fire Resisting Wall System from their local Stramit office. We do not sell direct to the public but our products are stocked by retail outlets across Australia.

Availability

This product is available Australia-wide. Lead times may vary depending on your location.

News and Case Studies

Check out Stramit’s latest news, product releases and updates, and case studies featuring our quality Aussie-made steel products.

General Information

The Stramit Uniguard™ Fire Resisting Wall System is suitable for most non-coastal conditions. Please check the relevant Stramit Technical Product Manual for material selection.

All building products need to be checked for compatibility with adjacent materials. These checks need to be for both direct contact between materials, and where water runs from one material to another.

Stramit products should be handled with care at all times to preserve the product capabilities and quality of the finish. Packs should always be kept dry and stored above ground level while on site.

If the products become wet, they should be separated, wiped and placed in the open to promote drying.

Stramit's fire-resisting wall product is protected in Australia by registered designs.

The Stramit Uniguard® Fire Resisting Wall System has been tested by Exova Warrington Aus Pty Ltd using the test criteria of AS1530.4-2005.

The Stramit Uniguard™ Fire Resisting Wall System has been tested by Warrington Fire Research, Victoria, and a copy of the report is available for download.

Stramit's cladding profiles have been comprehensively tested, including independent tests at the Cyclone Testing Station.

Technical Information

While formal data is not currently available, the Stramit Uniguard™ Fire Resisting Wall System has intrinsic acoustic properties that aid noise attenuation.

The walling shall be the Stramit Uniguard™ Fire Resisting Wall System where the external cladding is 0.42 or 0.48mm BMT Stramit® Corrugated, Monoclad® or Longspan® steel cladding. Design and installation must be in accordance with the manufacturer's published recommendations.

The Stramit Uniguard™ Fire Resisting Wall System provides a solution to the BCA requirements for external walls of buildings with floor areas less than 2000m2 in Class 7b and Class 8 buildings (factories and warehouses) of type C construction.

The system conforms to the BCA requirements for an 'alternative solution' (ie that can be demonstrated to be equivalent to the deemed-to-satisfy provisions). Testing has show that the Stramit's Uniguard™ system can meet the radiant heat flux exposure limits of Verification method CVI.

Full details of the testing, BCA alternative solution verification and system constraints and limitations are provided in the Warrington Fire Research Report numbers 40981B, 22765300-RPT01-R6.0 and subsequent appended opinions.

Copies of the reports are available from your local Stramit office.

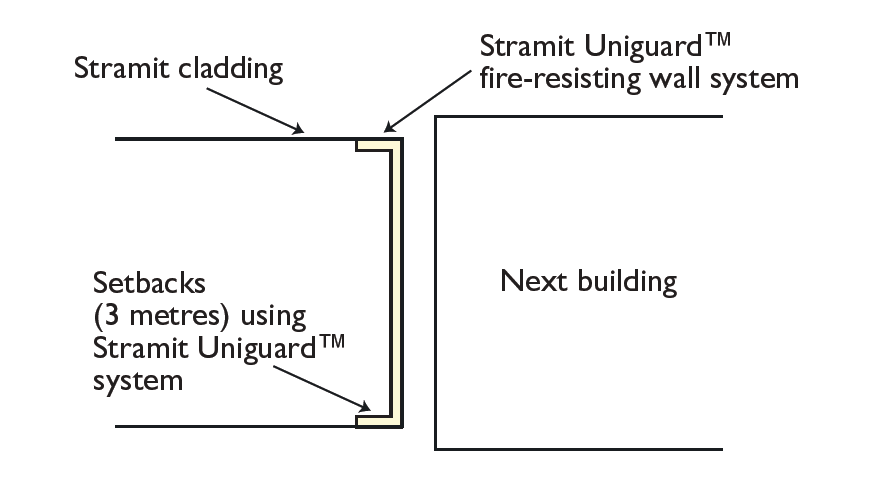

The Stramit Uniguard™ Fire Resisting Wall System allows external walls to be built right up to the boundary, if practical considerations allow.

Allowance for gutters and downpipes must be made when considering the proximity of the wall to the boundary. Only the fire resisting wall sections need to be constructed using the Stramit Uniguard™ system.

The remaining walls except for the 3-metre setbacks may be constructed using a conventional Stramit walling system except for the setbacks.

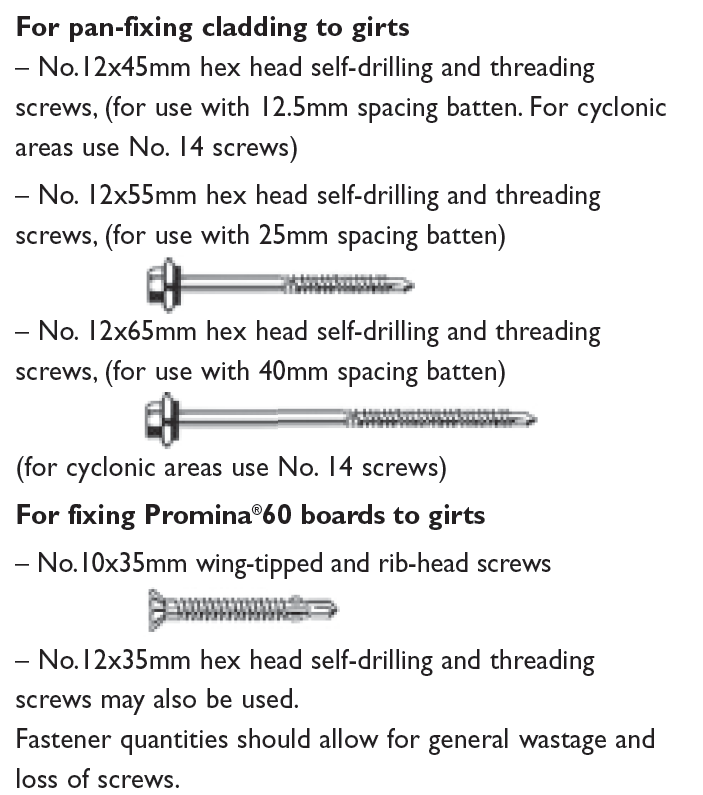

All fastening screws must conform to AS3566-Class 3 or 4. Sheeting fasteners should be hexagon-headed and may be used with sealing washers. All fastening screws must conform to AS3566-Class 3 or 4. Sheeting fasteners should be hexagon-headed and may be used with sealing washers.

The Promina® 60 board is manufactured from calcium silicate, which looks and feels like conventional fibrous cement board. The boards are supplied in a standard size of 2400 x 1200mm with a thickness of 15mm and a mass of approximately 41kg per board.

Stramit's cladding is manufactured from hi-tensile G550 COLORBOND® or ZINCALUME® steel. In some locations COLORBOND® Ultra steel may be available by arrangement or galvanised steel available for special service environments. COLORBOND® and COLORBOND® Ultra steel is in accordance with AS2728-Category 3 and, for the substrate, AS1397.

ZINCALUME® AZ150 and galvanised Z450 steel conform to AS1397. Spacing battens are made from Z350 GALVASPAN coated steel. Stramit has a comprehensive range of colours as standard. Ask your nearest Stramit location for colour availability.

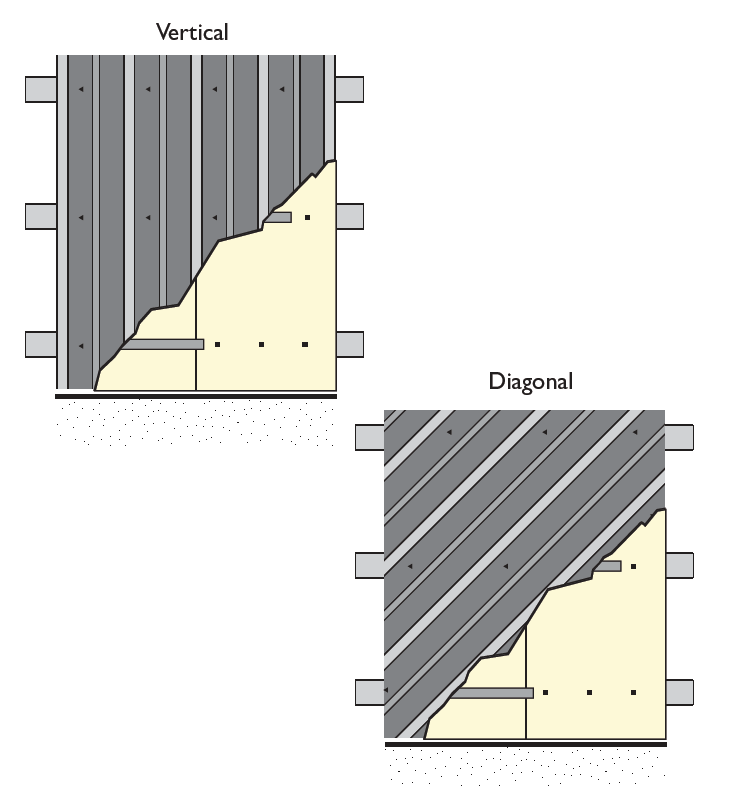

The steel cladding of the Stramit Uniguard™ Fire Resisting Wall System may be fixed with a vertical or diagonal orientation. The steel cladding orientation is primarily aesthetic and does not affect system performance.

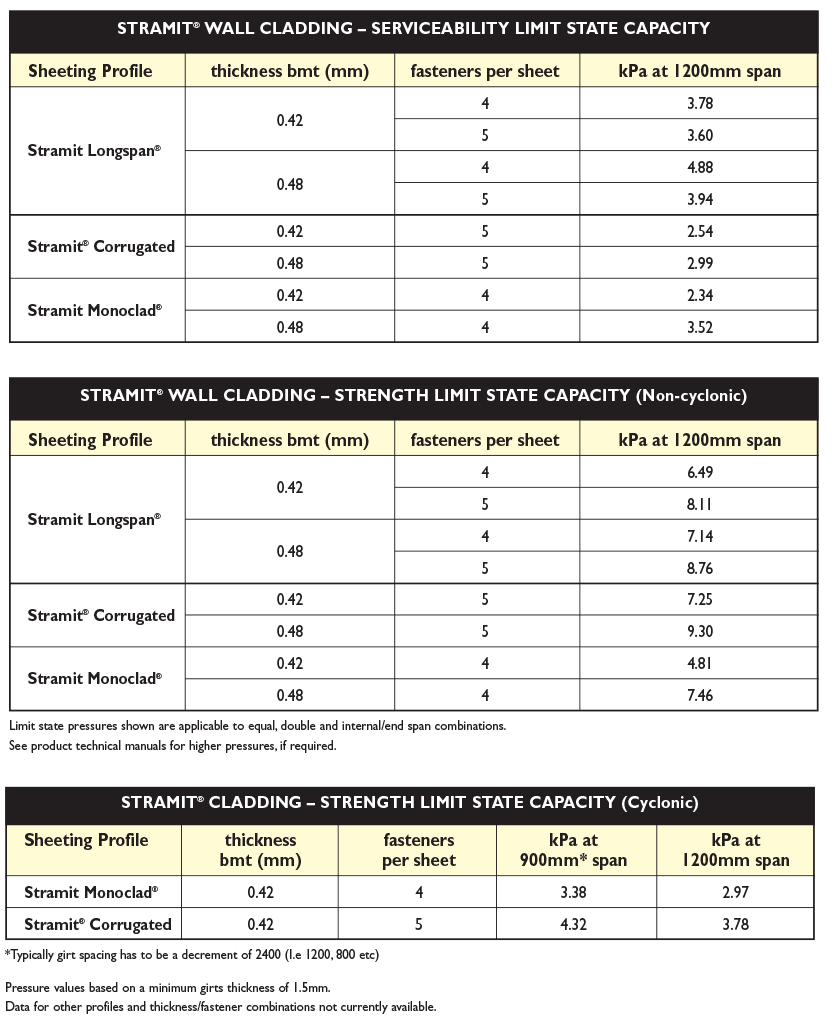

Limit state pressures shown below are applicable to equal, double and internal/end span combinations. Please refer to Stramit's Product Technical Manuals for higher pressures, if required.

Stramit Uniguard™ Fire Resisting Wall System is suitable for use in most categories . The system is limited to a maximum span of 1200mm. This is also the preferred girt spacing for optimum support of the thermal board. The bottom row of girts must be no more than 100mm from the concrete slab.

Girt spacings must also take account of the fastener layout of the lining boards. Board cantilevers must not exceed 300mm. Horizontal joins between boards must also be supported by a girt, with both boards overlapping the flange.

Please refer to the Stramit Uniguard™ Fire Resisting Wall System for detailed diagrams.

Wall girts (or top hats) should be specified using the Stramit Purlins, Girt & Bridging Product Technical Manual. Consideration should be given to the additional mass of the Promina®60 boards.

Promina®60 Boards for the Stramit Uniguard™ Fire Resisting Wall System are a standard size design, therefore checks for performance are not required.

Spacing battens for the Stramit Uniguard™ Fire Resisting Wall System do not require additional design checks. Wall Cladding wind resistance should be checked using the Stramit Technical Manual for either Stramit Corrugated, Monoclad or Longspan cladding.

The Stramit Uniguard™ Fire Resisting Wall System must not be compromised by any penetrations or non-fire resistant inclusions, such as windows, doors, piping or plumbing.

Installation Information

- Ensure all girts are in line and correctly installed. If alternative flashing arrangement is desired, please proceed to point 6.

- Fix the full-length Promina® board through its centre to the girt, using 3 fasteners keeping plum. Fasteners must not be used within 100mm of the board edge. The top of the board should rest against a girt, leaving enough of the girt so that the bottom of the next board overlaps the girt and is supported against inward movement. The joins do not need to be fastened at this stage because the boards will be held in place by the spacing battens and secured by the sheet fasteners.

- Butt the next board tightly up against the already attached board and fix as before. Repeat for any higher rows of boards.

- Line up spacing battens with the girts and fix temporarily with adhesive tape.

- Position and fix the bottom flashing.

- Position and fix the first cladding sheet, ensuring correct sheet overhangs. Ensure screws are not over-tightened and are in line with girt and spacing batten. Use a minimum of 4 fasteners per sheet at each support.

- Fix subsequent sheets, checking that sheet ends at the lower edge are exactly aligned. Ensure that cladding and flashing are fitted so that the Promina® 60 board is not visible from the outside. Use a minimum of 4 fasteners per sheet at each support.

- Position and fix edge trims.

Promina®60 boards can be painted using an acrylic paint if desired. The natural unpainted board colour is off-white.

Promina®60 board

When handling the board, please use a Class P2 (particulate) respirator, wear leather or cotton gloves and dustproof goggles if previous cutting or sanding causes potential dust generation. The boards should be carried upright to reduce handling damage.

Steel Cladding

Wear safety glasses with side shields when cutting or trimming steel products. Cut-resistant or leather gloves should be worn when handling steel products. Foot protection should be worn when handling and transporting products.

Exterior surfaces of metal product unwashed by rain, such as walls beneath eaves or awnings, can benefit from occasional washing to remove build-up of corrosive salts.

A simple visible inspection of the Promina®60 boards is recommended. Exterior surfaces of metal product unwashed by rain, such as walls beneath eaves or awnings, can benefit from occasional washing to remove build-up of corrosive salts.

To preserve the fire resistance qualities of the Promina®60 board, no holes should be created in the boards with items such as nails or poster pins.

Minor repairs may be made by adhering small patches of board using Promaseal® acrylic sealant. Any boards damaged during building must be replaced. If boards are cracked during subsequent use, they must be repaired. Small holes up to 50mm may be filled with Promat Promaseal® acrylic sealant.

Contact your local Stramit office for your further details on repair.

Promina® is a registered trade mark of Promat GmbH