Share with

FEATURES AND BENEFITS

COLOUR OPTIONS AND FINISHES

Various Half Round gutters are available, which can be cut to size. The maximum product length is 9.0m and the minimum length is 500mm. Available as slotted and plain.

Various Half Round gutters are available, which can be cut to size. The maximum product length is 9.0m and the minimum length is 500mm. Available as slotted and plain.

Various Half Round gutters are available, which can be cut to size. The maximum product length is 9.0m and the minimum length is 500mm. Available as slotted and plain.

Various Half Round gutters available, which can be cut to size. The maximum product length is 9.0m and the minimum length is 500mm. Available as slotted and plain.

Stramit® 150 Half Round Gutter

Various Half Round gutters available, which can be cut to size. Maximum product length is 9.0m, minimum length 500mm. Available as slotted and plain.

The Stramit 150 and 200 Half Round gutters are available to order only, in 6.0m length minimums.

The Stramit 150 and 200 Half Round gutters are available to order only, in 6.0m length minimums.

The Stramit Quarter Round Gutter is available in a minimum length of 1m and maximum length of 8.0m. Can be cut to length, with stop ends on the left or right hand side. For more information download the new brochure.

Stramit® Quarter Round Gutter WA

Where to Buy

Stramit account holders can buy Stramit® Half Round Gutters from their local Stramit office. We do not sell direct to the public but our products are stocked by retail outlets across Australia.

Availability

Stramit® Half Round Gutters are produced to suit local traditional shapes across Australia so products vary to suit the location. Please check with your local Stramit office or Product and Service Guide for a schedule of availability and whether the product can be cut to length.

News and Case Studies

Check out Stramit’s latest news, product releases and updates, and case studies featuring our quality Aussie-made steel products.

General Information

Stramit® Half Round Gutters coated with Zinc-Aluminium / Zinc-Aluminium-Magnesium alloy and COLORBOND® steel will give excellent durability in almost all locations more than 200m from a marine environment or in some light industrial applications.

Applications close to industrial or unusually corrosive environments will need to be individually assessed for durability. For these and installations closer to the coastline, please contact your local Stramit office for advice. External brackets for Stramit® Half Round Gutters should only be used in benign locations.

Stramit® Half Round Gutters should only be used with Stramit fascia products. Similarly, only use specified Stramit accessories when connecting Stramit® Half Round Gutters to Stramit® Fascia.

Hail

Stramit's rainwater products can resist impact from significantly-sized hail without damage. However, in hail prone areas consider placing gutter fronts well below roof level. This will help avoid the damming effect of hail which, if it allowed to build up onto the roof, can lead to overloading and gutter failure .

Snow

It is common practice not to use gutters in snow prone areas but to take care of roof run-off at ground level. Information on designing in snow areas can be found in Standards Australia Handbook HB 106 Guidelines for the design of structures in snow areas.

Stramit rainwater products should be handled with care at all times to preserve the product capabilities and quality of the finish. Packs should always be kept dry and stored above ground level while on site.

If the products become wet, they should be separated, wiped and placed in the open to promote drying.

High front gutters are commonly used in residential roof drainage systems to conceal the lower edge of roof cladding or tiles. These gutters form part of the roof drainage system, which is required to comply with the National Plumbing and Drainage Code AS/NZS 3500.3.

Details of the design process for roof drainage systems, which includes selecting overflow measures, are set out in this standard.

Most of Stramit® Half Round Gutters are supplied cut to length. Contact your local Stramit office or refer to the Stramit Product and Service Guide for your area for further detail.

Under the Environmental Planning and Assessment Act 1979 and its regulations, all building work must be carried out in accordance with the Building Code of Australia (BCA), now part of the National Construction Code (NCC).

In addition to referring to Australian Standards AS/NZS 3500.3, and AS/NZS 3500.5, the BCA also contains requirements for the disposal of surface water in Volume One, Performance Requirements FP1.2 and FP 1.3, and in Volume Two, Part 3.5.2, namely, Performance Requirement P2.2.1 and Clauses 3.5.2.1. to 3.5.2.5.

The most common means of satisfying these requirements for roof drainage (i.e. guttering) installations is by complying with the National Plumbing and Drainage Code AS/NZS 3500.3. Furthermore, in each state and territory it is necessary to satisfy the relevant regulations.

Stramit's Rainwater products are protected in Australia by registered designs.

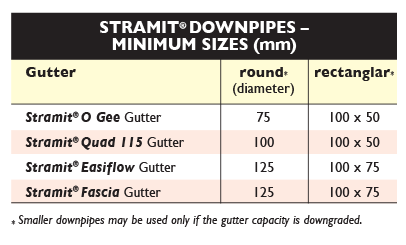

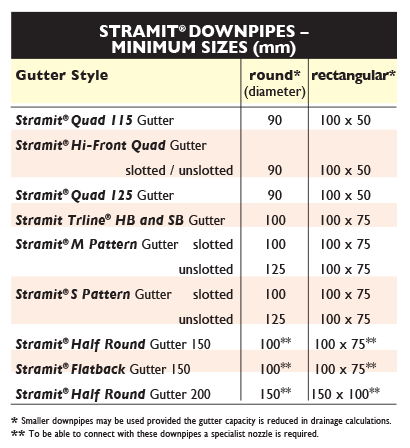

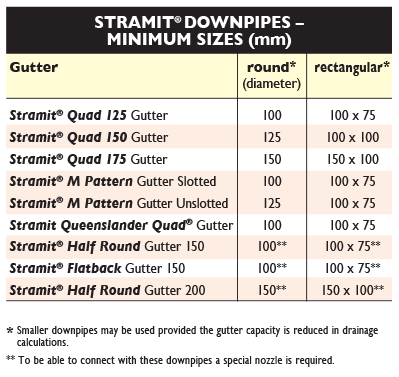

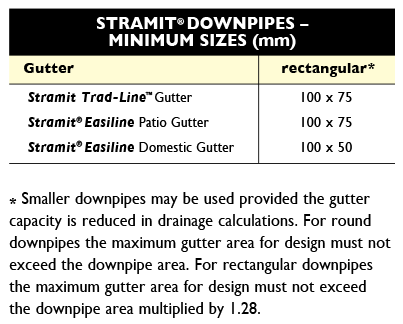

Sizing of minimum downpipe size relates only to the cross-sectional area of the chosen gutter. Refer to the table below for the minimum round and rectangular downpipe size for the half round gutter you plan to use.

NSW/ACT

QLD/NT

VIC/TAS/SA

WA

All Stramit rainwater products confirm with, or are equivalent to, AS/NZS 2179.1.

Stramit has in-house, purpose built testing equipment used to design, develop and improve products for the Australian market.

Many of our products are tested or witnessed by independent organisations. These include University of Technology, Sydney; James Cook University Cyclone Testing Station; The University of Sydney; and CSIRO.

The ongoing research and development activity ensure we remain at the forefront of innovation, design and consumer information.

Technical Information

The gutter shall be Stramit [insert Half Round Gutter type] as selected based on size and performance. Material shall be protected steel sheet to Australian Standard AS1397 with a minimum yield stress of 550MPa and an AM100/AZ150 coating with an oven-baked paint film of selected colour, or a plain AM125/AZ150 coating.

All accessories are to be fully compatible as recommended by the manufacturer. The product and its accessories shall be installed strictly in accordance with the manufacturer's recommendations. Flashings and all adjacent products shall be supplied in compatible materials as specified.

All work shall be fixed in a workman like manner, leaving the job clean and weather tight. All debris (screws, rivets, cuttings and filings, etc) shall be cleaned off daily. Repair all minor blemishes with touch up paint supplied by the manufacturer.

Note: Some products are supplied in 300MPa steel with galvanised Z275 coating.

In the design and detailing of a roof drainage system, consideration must be given to a range of factors.

These include:

- rainfall intensity

- roof catchment area

- gutter size/capacity, falls and outlets (sumps, rainwater heads, nozzles)

- downpipes (size, quantity and placement)

- overflow consideration

- material selection, and

- jointing.

Stramit recommends a minimum fall of 1 in 500 for all gutters as this is a design requirement for the gutter and downpipe selection table . Good fall reduces the risk of leaf and debris built-up that could otherwise effect durability.

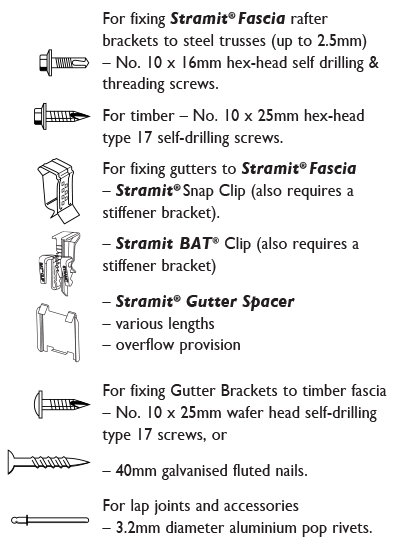

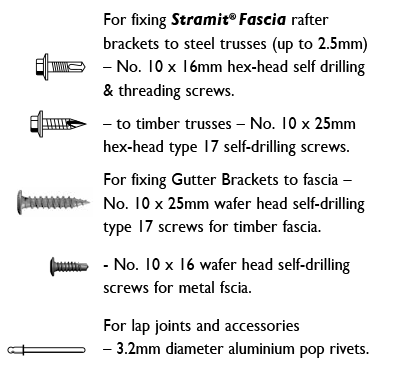

All fastening screws must conform to AS3566 – Class 3. For connecting brackets use the following.

ALL STATES (excl. WA)

WA

Gutter overflow needs to be considered when designing and installing gutter systems. The overflow devices should have adequate capacity and the roof drainage system must be in accordance with AS 3500.3.

Drainage from copper or lead products (including roof flashings) should not be allowed to discharge on to zinc/aluminium or aluminium/zinc/magnesium alloy or COLORBOND® steel components. Similarly, lead or copper components should not be installed in contact with zinc/aluminium or aluminium/zinc/magnesium alloy coated steel. Each of these combinations will lead to premature corrosion.

Drainage from copper, COLORBOND® and zinc/aluminium or aluminium/zinc/magnesium alloy coated steel, translucent (or other inert material) should not be allowed to discharge onto, or into, galvanised products.

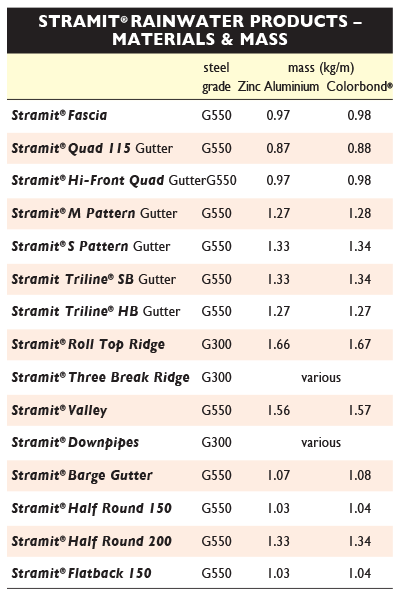

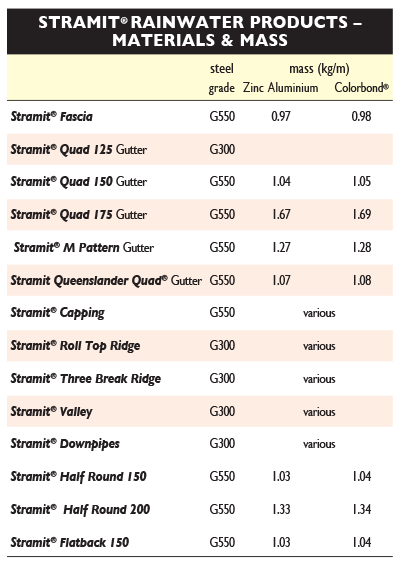

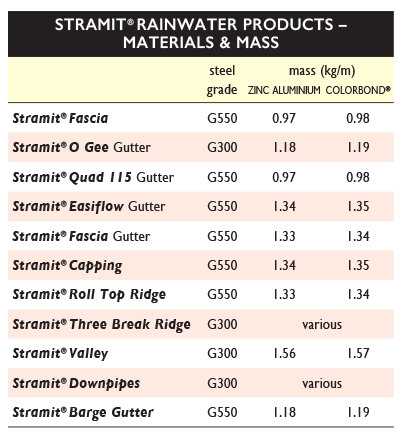

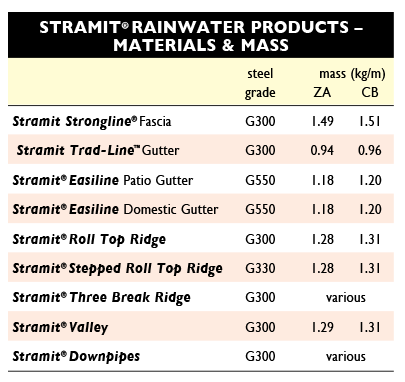

Stramit's rainwater products are manufactured from G550 and G300 Zinc Aluminium or Zinc Aluminium Magnesium coated steel (AZ150/AM125) or galvanized (Z275) in accordance with AS1397, and COLORBOND® steel with a coating conforming to AS2728.

Other coatings, grades and materials may be available, subject to enquiry.

NSW/ACT

QLD/NT

VIC/TAS/SA

WA

In all Australian states except Western Australia, overflow measures are not required for eaves gutters fitted to a verandah, or where the eave is greater than 450mm wide, with either no lining or sloping away from the building.

Slotted Stramit gutters give some overflow provision, when used with the Stramit® Snap Clip. A higher overflow volume can be catered for by providing the Stramit® Gutter Spacer or the Stramit BAT® Clip.

The Roof Run Length tables give the maximum sloped roof run length which can be used for the overflow through the slots, and back of gutter. These values are based on independent testing.

Where the Stramit® Gutter Spacer or BAT® Clip is used, they need to be installed as recommended in the installation leaflets provided with the product.

Alternative overflow measures

Overflow may also be addressed through alternative building design methods such as:

- Unlined eaves, where appropriate to the house design, to eliminate the issue.

- Gutter installed so that the gutter front is 10mm below the top of the fascia.

- Back flashing, where gutter support brackets allow for installation of back flashing (e.g. external brackets).

- The detailing and sizing of the selected overflow method/s is normally completed by the designer/installer, but must be adequate for the situation and must meet the relevant performance requirements of the NCC and Australian Standards.

The Building Code of Australia requires that where high-fronted gutters are installed provision must be made to avoid any overflow back into the roof or building structure by incorporating overflow measures or similar.

This requirement does not apply where the gutter is connected to a verandah or where the eave is more than 450mm wide, with either no lining or raked with a slope towards the gutter. Overflow design must be based on the 100 year ARI 5 minute duration rainfall intensity.

Methods of providing for overflow in the design and installation of roof drainage systems with high front gutters may include:

- slotted gutter front to allow for water overflow through the slots visible on the front face of the gutter

- a gap between the fascia and the gutter back, either by inserting a packer between the back of the gutter and the fascia or by employing proprietary systems and trade solutions

- specific overflow measures including an inverted downpipe drop/pop nozzle at high points in the gutter but set at a level below the fascia top

- stop ends cut down to a lower level to act as a weir; the stop end weirs could be hidden at the high point of the gutter and designed as part of an expansion joint

- rainwater heads with overflow weir, or

- holes, slot, or weir at downpipes.

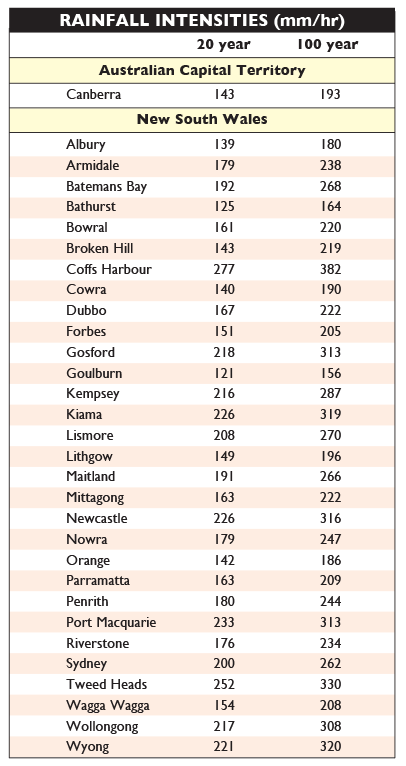

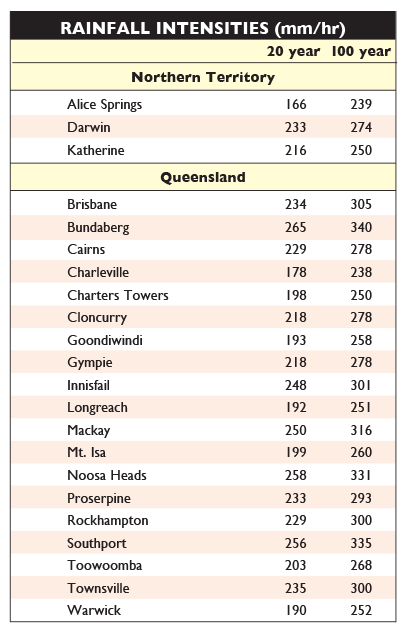

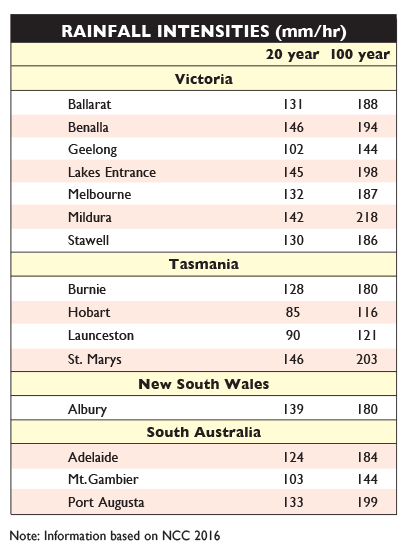

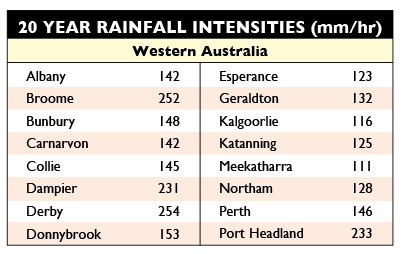

Rainfall intensity values in the tables below are for 20 and 100 year ARI, 5 minute durations and have been derived from the National Construction Code 2016. It should however be emphasised that the extent and longevity of records in Australia are limited and any such data therefore carries with it a degree of uncertainty.

The 20 year ARI values should only be used for external eave gutters. For internal/box gutters and overflow design use the 100 year ARI values included in the tables. Specific data for any location can be obtained from the Australian Bureau of Meteorology.

NSW/ACT

QLD/NT

VIC/TAS/SA

WA

In all Australian states except Western Australia, determining the maximum sloped roof run length involves taking into account the additional length of roof which contributes to the flow in any one position when there is a roof penetration or spreader.

In these positions, the effective roof run length would be longer than the distance from the ridge to the eaves. A simplified method of finding this length is shown in the illustration. In this case, the maximum roof run length is 14m for a 10m length of roof due to the penetration 4m down from the ridge.

If the catchment area is known, the roof run length can be found by dividing the area by the length of gutter it feeds into.

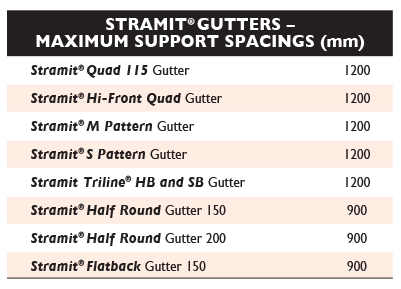

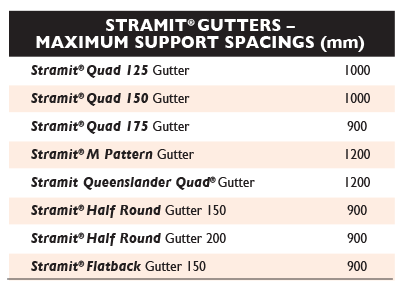

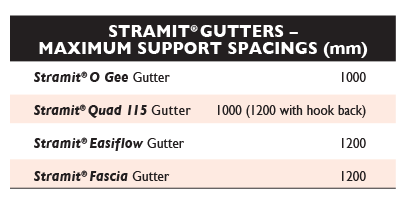

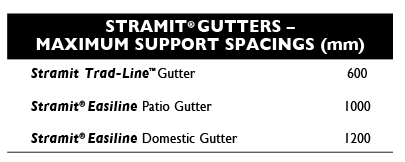

Stramit® Gutters require the correct proprietary Stramit brackets (or snap clip/stiffener bracket combination) for support at spacing no greater than those shown in the following table.

NSW/ACT

QLD/NT

VIC/TAS/SA

WA

Gutter runs in excess of 20 metres require expansion joints.

Installation Information

Stramit's rainwater products can be easily cut, where required, using a fine-toothed hacksaw and tin snips. Please dispose of any off-cuts carefully.

While there may be variations between states, contractors who install guttering systems are generally required to hold an appropriate licence. The work is required to comply with the appropriate codes and standards. Statutory warranties normally apply and consumers have a right to lodge a complaint with the appropriate authority.

During the installation of the roof drainage system, particular attention should be given to the following:

- The use of compatible materials for drainage system components, leaf-guard system components and fasteners/sealants to connect and seal the components.

- The position of the gutter in relation to the fascia.

- Installation of the specified gutter and downpipes, and ensuring that downpipes are installed in the correct locations and numbers.

- Gutter fall, ensuring sufficient fall in the direction of the downpipes.

- Overflow must be allowed for and specific components installed where required.

- All debris and loose waste materials (swarf, fasteners, etc.) must be cleaned off at the end of each day and at the completion of the installation, to prevent blockages of the drainage system or deterioration of the individual components, and

- Any protective films should also be removed as part of the installation process.

Stramit recommends installers follow the installation code for metal roofing and wall cladding as outlined in the Standard Australia Handbook - HB39.

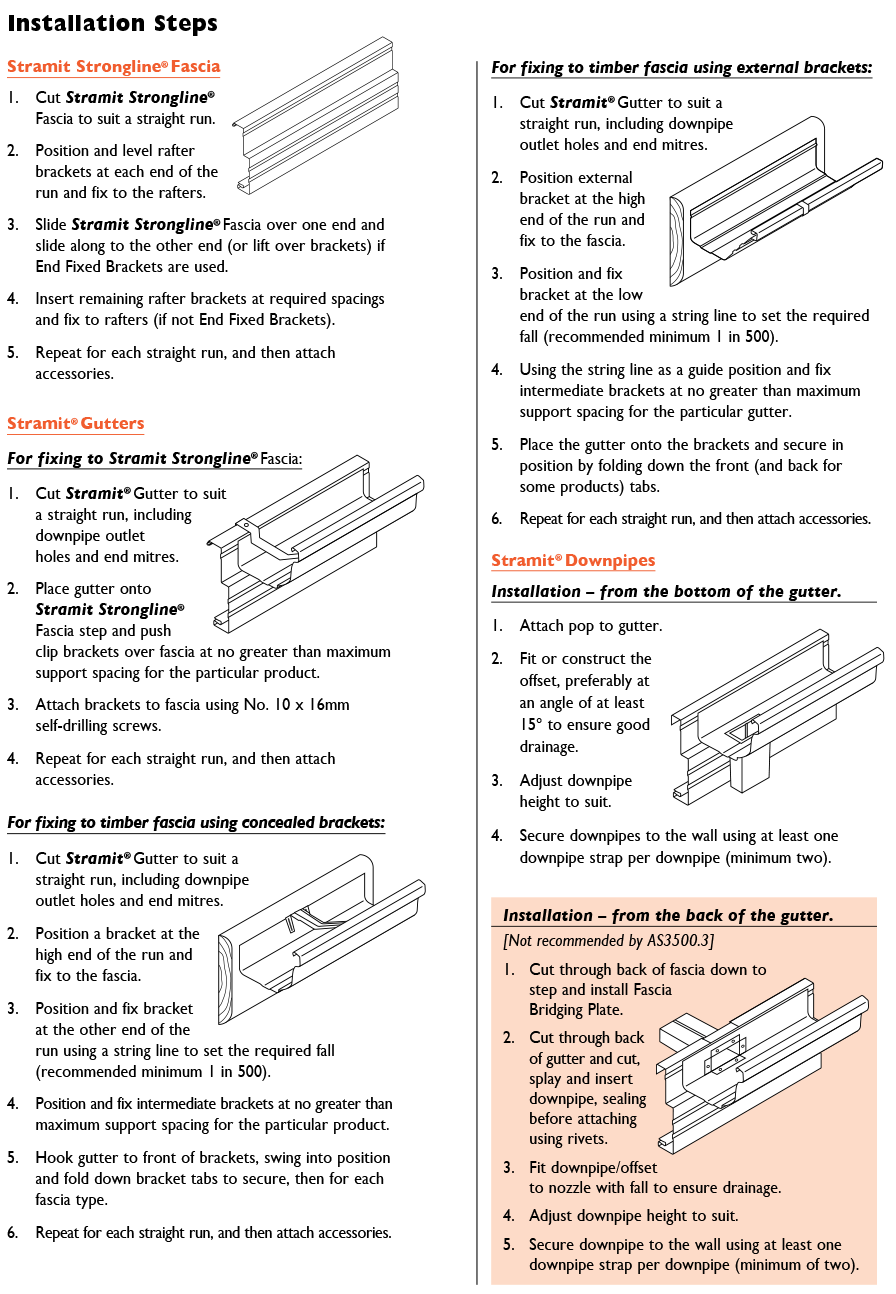

INSTALLATION STEPS

STRAMIT STRONGLINE® FASCIA

- Cut Stramit Strongline® Fascia to suit a straight run.

- Position and level rafter brackets at each end of the run and fix to the rafters.

- Slide Stramit Strongline® Fascia over one end and slide along to the other end (or lift over brackets) if End Fixed Brackets are used.

- Insert remaining rafter brackets at required spacings and fix to rafters (if not End Fixed Brackets).

- Repeat for each straight run, and then attach accessories.

STRAMIT® GUTTERS

For fixing to Stramit Strongline® Fascia:

- Cut Stramit® Gutter to suit a straight run, including downpipe outlet holes and end mitres.

- Place gutter onto Stramit Strongline® Fascia step and push clip brackets over fascia at no greater than maximum support spacing for the particular product.

- Attach brackets to fascia using No. 10 x 16mm self-drilling screws.

- Repeat for each straight run, and then attach accessories.

For fixing to timber fascia using concealed brackets:

- Cut Stramit® Gutter to suit a straight run, including downpipe outlet holes and end mitres.

- Position a bracket at the high end of the run and fix to the fascia.

- Position and fix bracket at the other end of the run using a string line to set the required fall (recommended minimum 1 in 500).

- Position and fix intermediate brackets at no greater than maximum support spacing for the particular product.

- Hook gutter to front of brackets, swing into position and fold down bracket tabs to secure, then for each fascia type.

- Repeat for each straight run, and then attach accessories.

For fixing to timber fascia using external brackets:

- Cut Stramit® Gutter to suit a straight run, including downpipe outlet holes and end mitres.

- Position external bracket at the high end of the run and fix to the fascia.

- Position and fix bracket at the low end of the run using a string line to set the required fall (recommended minimum 1 in 500).

- Using the string line as a guide position and fix intermediate brackets at no greater than maximum support spacing for the particular gutter.

- Place the gutter onto the brackets and secure in position by folding down the front (and back for some products) tabs.

- Repeat for each straight run, and then attach accessories.

STRAMIT® DOWNPIPES

Installation – from the bottom of the gutter

- Attach pop to sole of gutter.

- Fit or construct the offset, preferably at an angle of at least 15° to ensure good drainage.

- Adjust downpipe height to suit.

- Secure downpipes to the wall using at least one downpipe strap per downpipe (minimum two).

Installation – from the back of the gutter.

[Not recommended by AS/NZS 350 0.3]

- Cut through back of fascia down to step and install Fascia Bridging Plate.

- Cut through back of gutter and cut, splay and insert downpipe, sealing before attaching using rivets.

- Fit downpipe/offset to nozzle with fall to ensure drainage.

- Adjust downpipe height to suit.

- Secure downpipe to the wall using at least one downpipe strap per downpipe (minimum of two).

Stramit's rainwater products are available in COLORBOND® steel colours. However should painting of Zinc Aluminium / Zinc Aluminium Magnesium coated steel products be required, use the following procedure.

A weathering period of two weeks following installation will make painting easier. Clean the rainwater product immediately prior to painting. Dirt can be washed off using water with mild detergent. Any grease marks should be wiped away with paint thinners.

In benign locations good quality acrylic paint will give satisfactory performance. First use a low-gloss water-borne acrylic primer. Finish with water-borne acrylic gloss, or your choice of gloss level.

Use only neutral-cure silicone for sealing joints when using Stramit's rainwater products. Take care to avoid pockets in joints which may hold moisture and potentially reduce durability.

Consideration should be given to handling and installation issues as part of site induction safety procedures. Specific consideration should be given to pack handling , avoidance of cuts, trips, slips and falls, long section handling, particularly in windy conditions, section cutting procedures and surface temperature on sunny days.

Personal Protection Equipment (PPE) should always be used, including cut resistant or leather gloves when handling and transporting product and appropriate footwear when handling long lengths.

Stramit's rainwater products manufactured in the COLORBOND® range of colours are supplied with a protective strippable coating. This should be removed at the last possible stage during the installation process.

It is possible to selectively move the coating to one side to avoid fastenings and joints before finally remove the coating from the installed product. Do not leave the products with strippable coating intact exposed to direct sunlight for more than a week or it can become difficult to remove.

Stramit rainwater products can benefit from occasional washing if they're not flushed out regularly. These areas include portions of fascia and the underside of accompanying gutters.

In the longer term, the ability of a roof drainage system to handle overflow depends on you cleaning and maintaining your gutters regularly so they can perform to their optimum capacity.

It's therefore worth considering the following maintenance regime:

- Use appropriately-sized gutters set well below the roof edge with a good fall and large downpipes with well angled offsets to avoid corner blockages.

- Clean frequently and remove overhanging vegetation.

- Install mesh guard or a perforated gutter covering, noting the guard/covering and the gutter needs to be cleaned and checked regularly.

- Ensure protective guards are material-compatible with the gutter.

Following a regular and adequate maintenance regime is also a requirement for your warranty.