Share with

- One-piece innovative design

- Manufactured from COLORBOND® steel

- Available in lengths up to 9m for larger spans

- Australian-made

- Excellent performance

- Can be cut to length

- Large range of complementary accessories available, powder-coated to match

- Performance tested and non-combustible

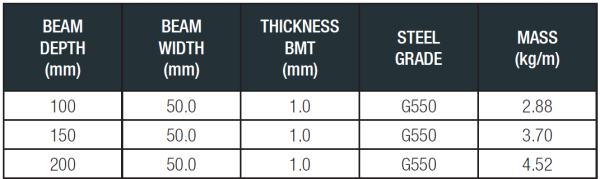

Sunset® beams are manufactured from COLORBOND® steel, 1.0mm BMT G550 AM100 high tensile coated steel.

High gloss finish: COLORBOND® steel Classic Cream™, COLORBOND® steel Paperbark®, COLORBOND® steel Thredbo White®

Standard finish: COLORBOND® steel Monument®, COLORBOND® steel Woodland Grey®, COLORBOND® steel Dune®

Standard Steel Standard Steel Standard Steel Standard Steel Standard Steel Standard Steel

Thredbo White®

COLORBOND® Classic Cream™

COLORBOND® Paperbark®

COLORBOND® Dune®

COLORBOND® Woodland Grey®

COLORBOND® Monument®

Certain colour options and finishes may be subject to availability and lead times may vary from site to site. Other colours may be available, subject to minimum order quantities and additional lead times. Please contact your local Stramit office to confirm.

Where to Buy

Stramit account holders can buy Sunset® Patio Beams from their local Stramit office. We do not sell direct to the public but our products are stocked by retail outlets across Australia.

Availability

This product is available Australia-wide excluding the Northern Territory, Western Australia and Tasmania. Lead times may vary depending on location.

News and Case Studies

Check out Stramit’s latest news, product releases and updates, and case studies featuring our quality Aussie-made steel products.

General Information

Contact your local Stramit office for more information on lead time to your area, as timing will be subject to the delivery location, quantity and material availability, or can be at a pre- arranged date and time. Please ensure that suitable arrangements have been made for truck unloading, as this is the responsibility of the receiver. Pack mass may be up to 300kg.

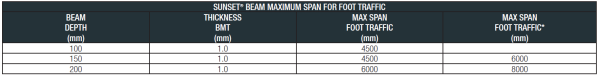

Stramit does not recommend walking on the Sunset® beam. Limited testing on horizontal beams have shown limitations to span lengths shown below.

* These spans need fixing together of two beam layers at top with wafer head size 10-16x16mm screws, 750mm apart.

Stramit structural products should be handled with care.

Packs should always be kept dry and stored above ground level while on site. If the sections have become wet, they should be separated, wiped and placed in the open to promote drying.

Stramit® beams are supplied cut-to-length. When designing or transporting long products ensure that the length is within the limit of the local transport authority regulations. The manufacturing tolerance on the length of product supplied is +0, -15mm.

Stramit® beams can be ordered directly, through distributors, or supplied and fixed by a patio installer.

Stramit's structural products are protected in Australia by registered designs.

Contact our technical services consultants if you require further information or advice for your local conditions and practices.

Technical Information

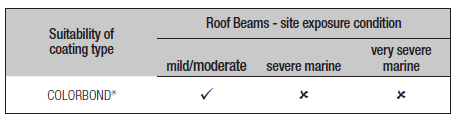

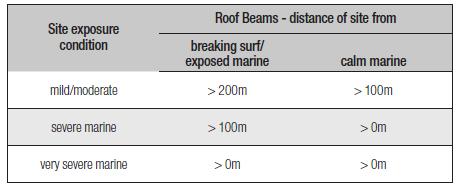

Stramit® Sunset® beam will give excellent durability in almost all locations. It is however important to choose the correct coating for each application environment as shown in the table below. Durability recommendations do vary based on the application of the product. Please read the tables below carefully.

The approximate site exposure conditions in the table above are defined below.

The suitability and exposure tables above are current at the time of publication and are guidelines only; conditions will vary from site to site. Please check the Bluescope Technical Bulletins at www.bluescopesteel.com.au for the latest information and guidance on selection, maintenance and durability. If uncertain about the appropriate coating for a particular application, or if the product is to be used in environments affected by industrial emissions, fossil fuel combustion, animal farming, or has unwashed areas, please contact your nearest Stramit office for advice.

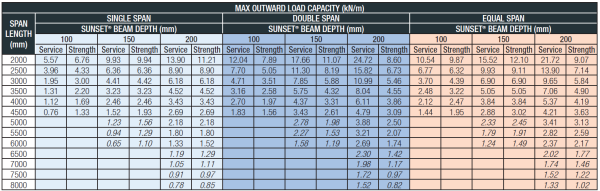

Upward Loads

Note:

1. Serviceability limit state load based on Span/150 deflection limit

2. Based on double skin of the beam at the top

3. Accounts for hogging and sagging moment, shear and combined shear & bending checks

4. Stramit does not recommend walking on the Sunset(R) beams. Some testing has however been carried out on horizontal beams. For spans highlighted in the above table by italic font, it would be necessary to fix the layers of the top surface together using wafer head size 10-16x16 screws at 750mm centres.

5. Connection of beam bracket to support must be checked.

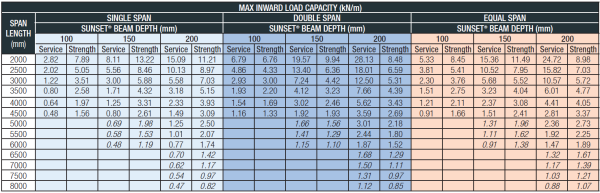

Downward Loads

Note:

1. Serviceability limit state load based on Span/300 deflection limit

2. Based on double skin of the beam at the top

3. Accounts for hogging and sagging moment, shear and combined shear & bending checks

4. Stramit does not recommend walking on the Sunset(R) beams. Some testing has however been carried out on horizontal beams. For spans highlighted in the above table by italic font, it would be necessary to fix the layers of the top surface together using wafer head size 10-16x16 screws at 750mm centres.

5. Connection of beam bracket to support must be checked.

Stramit Sunset® beams are manufactured from high tensile G550 colour coated steel with aluminum-zinc-magnesium alloy coated steel.

Colour coated steels are in accordance with AS/NZS 2728 - Category 3 and for the substrate, with AS1397. Aluminum-zinc-magnesium alloy coated AM100 steel conforms to AS1397.

Stramit has a range of 6 colours as standard. Ask your nearest Stramit location for colour availability.

SUNSET® BEAM THICKNESS, GRADE AND MASS

Installation Information

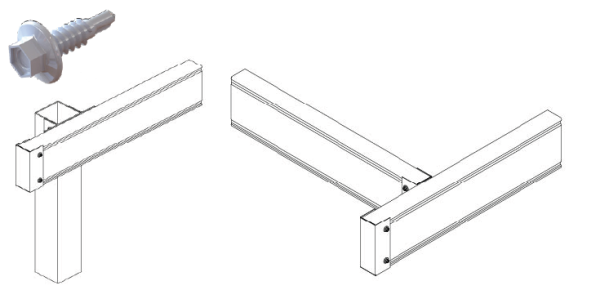

The numbers/details of screws used on the beams are as follows:

100, 150: To attach a Frame Bracket to a main support: 4 screws through the back face of

the bracket.

To attach a Beam to a Frame Bracket: 2 screws through each side of the web (brackets have pre-drilled holes), total: 4

200: To attach a Frame Bracket to a main support: 6 screws through the back face of the bracket.

To attach a Beam to a Frame Bracket: 3 screws at each side of the web (brackets have pre-drilled holes), total: 6

Screws: hex-head screws 12-14x20mm

Consideration should be given to handling and installation issues as part of site induction safety procedures. Specific consideration should be given to pack handling, and avoidance of cuts, trips, slips and falls, long section handling, particularly in windy conditions, and surface temperature on sunny days.

Wear safety glasses with side shields when cutting or trimming product. Cut resistant or leather gloves should be worn when handling product. Foot protection should be warn when handling and transporting product.

Stramit recommends that good trade practice be followed when using these products, as outlined in AISC/Australian Standards HB62 part 1 and HB39.